Home / Furnaces for zinc alloys

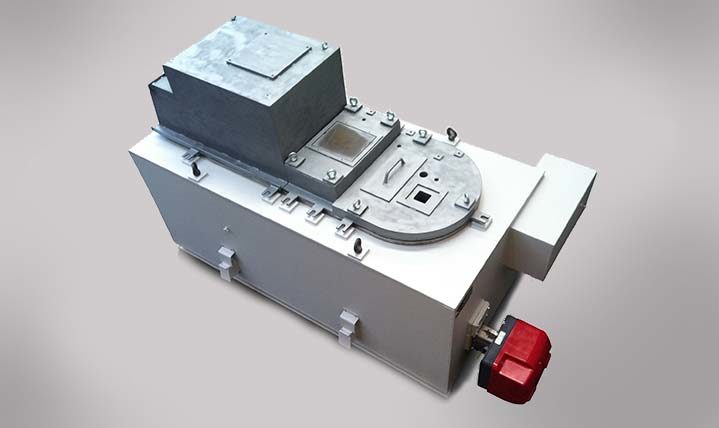

FURNACES FOR ZINC ALLOYS

HOW A FURNACE FOR ZINC ALLOY IS MADE

The crucible is made out of stainless steel and manufactured by Ditta Musto.

Control cabinet with PLC and temperature regulation.

0% -100% power control by static relay (zinc furnace with heating elements for melting) and amperage display on PLC with graph and temperature and power curves. Tilting version with hydraulic cylinder.

APPLICATIONS

Furnaces specifically fabricated for zinc alloys can be manufactured for casting, melting or recycling

and can be either gas or electric heated.

ADVANTAGES

The primary goal of our engineering team is to supply you with an efficient

furnace that allows you to save money in terms of energy in casting zinc alloys. Insulation

is one of the main features, ensuring minimal heat loss for customers.

UNIQUENESS

All components and devices are specifically chosen by our technicians to ensure maximum duration and avoid unexpected production downtime. All Musto furnaces for zinc alloys comply with European “green impact” standards. All components are recyclable and certified.

TECHNICAL SPECS

- Option of fitting a manual or pneumatically controlled insulated cover (saving melting time and energy).

- For the electric furnace: the electric heating elements can be replaced without removing the crucible (saving time during shutdowns).

- Type K thermocouple control in the metal bath.

- Safety regulation by type K thermocouple in the furnace.

- Capacities can range from 200 to 10,000 kilos, depending on final use.

- Possibility to supply small laboratory furnaces with a capacity from 2 to 50 kilos.