Home / Crucibles for magnesium alloys

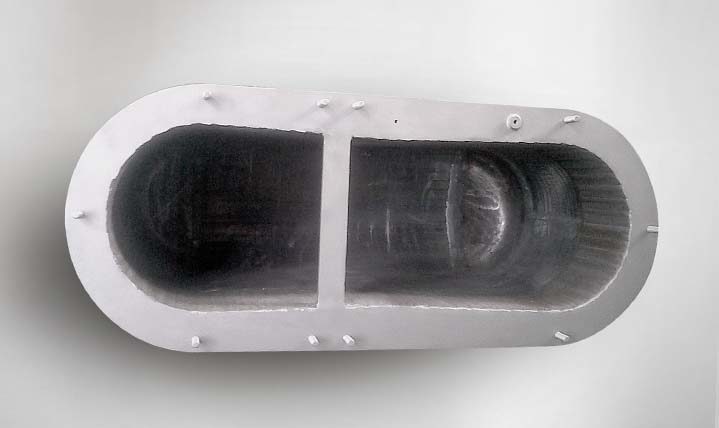

CRUCIBLES FOR MAGNESIUM ALLOYS

some objects produced with our magnesium crucibles

HOW A CRUCIBLES FOR MAGNESIUM ALLOYS IS MADE

The branded Musto crucibles for magnesium are sold and recognized all over the world for their technical details.

The Company has studied a specific, unique process to manufacture the magnesium crucible. The crucibles are in fact manufactured in the basic materials required to cast magnesium alloys but are then subjected to a special welded coating process that prolongs the crucible’s life span and offers more reliability in terms of avoiding cracks in the main welding seams.

This process was created by special welding robots designed especially for this product. Our team has been working in the magnesium alloys field for many years and takes great care over all customer.

For this reason we always engineer our crucibles for casting magnesium alloys to improve their final use, in terms of reliability and lifetime.

Their engineering concerns the manufacturing process and the thickness choice for crucible materials, the flange, the bottom side. Another important topic is the choice of the grade of steel to be used for the crucible and the materials to be used for the internal and external coating.

On this point we are very flexible if compared to any other competitors because we adapt the crucible especially fabricated for magnesium alloys to the customers’ needs , in order to offer a longer life and solve corrosion and oxidization problems.

Our crucibles work alongside the customer and improve over time building a collaborative relationship. The passion for magnesium alloys and the continuous research on materials have led Musto to renew the steels used to make the magnesium crucibles. In recent years, Ditta Musto has launched on the market a new type of crucible for magnesium alloys, very suitable for medium-sized die casting crucibles.

They no longer require a welded coating and provide a very long life without suffering from corrosion or deformation.

APPLICATIONS

Molten metal crucibles suitable for magnesium alloys are used in many different industrial fields to make different components such as hydraulic pumps for compressors, seats for helicopters, aircraft engines, notebook cases, mobile phone frames, personal computers, loudspeakers, camera frames, joysticks , sports goggles, rods, ski boot levers, bicycle frames, fishing rod reels and much more.

Crucibles for casting all magnesium alloys can be manufactured in any size and shape, for any type of castings : low pressure, die-casting, gravity casting, sand casting and recycling. Flexibility in fabrication and fast delivery are a flagship of our production for crucibles for magnesium alloys.

For all standard die-casting machines we have redesigned our own manufacturing drawings in order to improve the life of the crucibles for magnesium alloys and avoid deformation in the short terms.

To sum things, the fabrication of molten metal crucibles for melting magnesium alloys is quite complex and the afore parameters demonstrate the reason why our branded Ditta Musto crucibles for magnesium alloys are one of the most requested.

ADVANTAGES

Magnesium crucibles. Crucibles fabricated for magnesium alloys are a source of pride for Musto et Bureau Srl: an innovative product with an all encompassing performance if compared to any other product on the market, manufactured with new production processes.

The crucible is competitive in economic terms but higher performance features can be adjusted to customer needs.

UNIQUENESS

Research and innovation. The molten metal crucible for magnesium alloys is the Musto core business product. In 1965 Musto was the first Company in Italy to start manufacturing crucibles for magnesium, when application of magnesium alloys was still very restricted.

The Musto process was particular, made out of basic steel, nickelfree, with a special outer stainless steel coating . This manufacture of Musto crucibles for magnesium alloys was different to the rest of the world and soon made the brand stand our from all the other crucible manufacturers.

The crucibles for magnesium alloys manufacturing process has been innovated continuously during the last 20 years, as a result of the latest changes in the magnesium field.

There were several challenges involved, including study of new materials, new designs, shapes and a new manufacturing technique. The Company dedicated itself to finding new ways to prolong the lifetime of the crucibles for magnesium alloys as there were many requests for this process.

TECHNICAL SPECS

- Manufactured in any size and shape

- Manufactured for all standard die casting machines or based on the customer’s drawing

- Manufactured in mild steel, nickelfree, or in special stainless steel suitable to Mg castings

- Crucibles up to 40 mm thick possible

- A special steel coating can be added to the crucible outer side and at different heights from the bottom

- A special inside chrome coating can be added up to the height of the level bath

- Capacity from 10 Kgs tol 15000 Kgs of magnesium alloys

- For hot and cold chamber diecasting, for gravity castings, for smelting, recycling and holding

- Qualified weldings and welding quality controls performed before delivery

- Supplied with threaded lifting holes on the flange

- Handles or a baffle can be added

- Supplied with crucible maintenance instructions

- Engineered especially for the heating type , gas or electric

- A cover to match the flange or the top of the crucible ca be made

- All DITTA MUSTO products are insured

WIKI

Magnesium alloys for a lighter world. In fact, magnesium is one of the lightest among the useful metals, it has good shock absorption, and good characteristics for die casting.

Its main characteristics can be summarized in: greater respect for the environment ( thanks to the absence of protective gases during casting ), greater resistance to oxidation and lower tendancy to ignition, better mechanical strength (strength and elongation at break), greater resistance to cracks, greater hardness, total recyclability ( easy to reuse scraps), good alloy fluidity and castability.

The drive towards respect for the environment and optimization of the product life cycle is an element that characterizes the present moment and the next few years and leads towards product innovation in all industrial sectors.

Magnesium does not only contribute to reducing consumption, thanks to its lightness, but also guarantees greater respect for the environment during the production process. This process require a special crucible.

This is obviously an advantage especially in the automotive field which has so many applications: car doors, seats, chassis, wheels, engine blocks, pistons, inlet piping, wishbone, transmission cases, clutch cases and so on.

The strengths of this metal are its extremely low density (1.7 kg / dm3), exceptional workability and being easily used in all imaginable melting processes, thanks to its excellent castability, moreover, combined with a rather low melting temperature (about 650 ° C).

The recyclability of magnesium is extraordinary; it can be remelted with very low energy consumption.