Home / Crucibles for lead tin and non ferrous alloys

CRUCIBLES FOR LEAD, TIN AND NON FERROUS ALLOYS

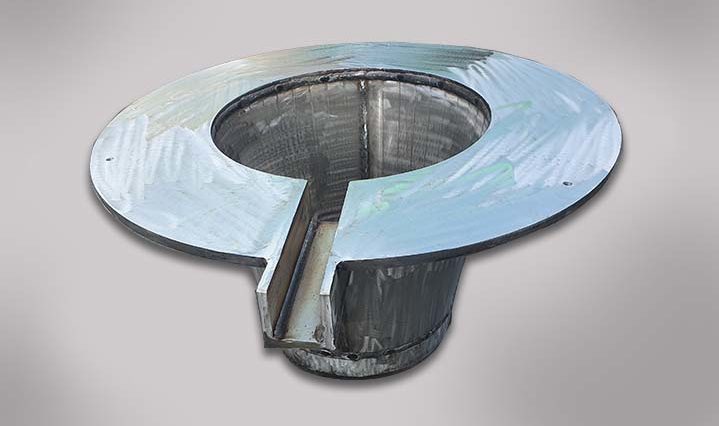

some objects produced with our other metals crucibles

HOW A CRUCIBLE FOR TIN AND LEAD IS MADE

The Musto brand crucibles for lead and tin are made of steel that can be adapted to the casting temperatures of these two alloys and can be engineered in all shapes and sizes, according to the size of the customer’s furnace.

APPLICATIONS

Crucibles for tin and lead can be manufactured in any size and shape, for any type of casting. Flexibility in fabrication and fast delivery are a flagship of our production for crucibles for the alloys of non ferrous metals.

For all machines we redesign our own manufacturing drawings in order to improve the life span of the crucibles and avoid short term deformation.

ADVANTAGES

Crucibles for tin, lead and other non ferrous alloys are commonly manufactured by Musto et Bureau Srl: they are replacing the refractory crucibles for non ferrous alloys because their life span is practically endless and they avoid possible cracks forming or production stops.

The crucible for tin and lead casting is competitive in economic terms, especially if compared to its lifetime, but higher performance features can be adjusted to customer needs.

UNIQUENESS

Research and innovation. The crucibles for tin, lead and non ferrous alloys are another product manufactured by Ditta Musto. Non ferrous alloys such as tin and lead melt at very low temperatures, so Musto can supply to this type of special steel crucible castors, suitable for their applications, and can assure them a longer life than a standard crucible.

Manufacturing molten crucibles for tin and lead alloys is very common but Ditta Musto is well known for manufacturing them with qualified engineering. The process to manufacture this type of crucibles for non ferrous alloys has been continuosly innovated with automatic welding procedures.

TECHNICAL SPECS

- Manufactured in any size and shape

- Possibility to manufacture crucible up to 40 mm thick

- Different grades of steel can be used

- Qualified welding and welding quality controls performed before delivery

- Handles can be added. Supplied with crucible maintenance instructions

- Engineered especially for the heating type , gas or electric

- A cover to match the flange or the top of the crucible can be supplied

- All DITTA MUSTO products are insured

WIKI

Lead has a melting temperature of 327 ° C and although it is forbidden in most industrial processes because it is highly dangerous due to its toxicity, it is still used in construction, in the production of automotive batteries, of bullets, in the fishery sector and, in the liquid state, as a coolant in nuclear reactors. Lead is not radioactive: it absorbs high frequency rays and is therefore used to produce shields.

Tin melts at a very low temperature, 231.92 ° C

It can be bonded to both copper and iron (and steel), to prevent corrosion: one of the best known applications is the production of tinplate containers, such as cans or canned goods, to contain drinks and food.

It is the metal used to make the welds – on copper and lead – and is essential during glass processing: to obtain the so-called floating glass. In fact, molten glass, when it comes out of the furnace, is poured on a tin bath – also molten – to obtain the plates.These processes need to be executed with a special crucible.