Home / Company

HISTORY

HISTORY

BEGINNINGS

In 1965, the Italian Society for Magnesium and Magnesium Alloys of Bolzano was producing a significant amount of magnesium alloys, with large furnaces equipped with cast iron crucibles, at a high cost since they had to be frequently replaced.

The engineering department then decided to research new materials and new shapes that were more suitable for their crucibles and passed this information on to a skilled craftsman who could make the new product.

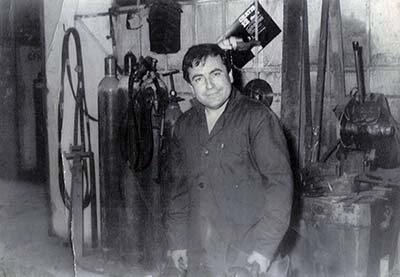

This led to the founding of a small artisan company owned by Ciriaco Musto, and its collaboration with the Society of Bolzano proved to be a winning partnership in the long term. This small company will become in future Ditta Musto.

Over the years, magnesium became increasingly used for all purposes and was applied in various fields. Ditta Musto company gained experience and became the trusted

workshop for all Italian foundries that were starting to smelt this innovative light metal and therefore needed crucibles.

Once again, thanks to the collaboration of other customers that were using cast iron crucibles for smelting zinc alloys, Ciriaco Musto began manufacturing the new crucible, which was made out of stainless steel.

Until then, zinc alloy foundries were exclusively using cast iron crucibles and the defects associated with this material (porosity, possibility of cracks, request for stock replacement, breakage and production downtime) entailed high costs.

The new stainless steel crucible, first manufactured by Mr. Musto, had eliminated all the production problems caused by the cast iron one. In a short span of time, Ditta Musto began manufacturing stainless steel crucibles in all shapes and sizes and, given the large demand, they became the company's main product within just a few years.

Despite producing high-quality magnesium and zinc crucibles, the company experienced a crisis and the Italian market slowed down considerably. Patrizia Musto, who had witnessed her father's work at his small company while keeping an eye on the global market, came up with the idea of exporting products that were not yet available in the global foundry market.

For this reason, Patrizia decided to invest in GIFA, the leading International Foundry Trade Fair, and to introduce her father's manufacturing abroad. The German market showed great appreciation for Ditta Musto's crucibles and, thanks to these innovative products, Ditta Musto was able to distinguish itself in just a short amount of time.

These "Made in Italy" quality crucibles were very well received by the foreign market, thus allowing Patrizia Musto to carry on her father's business.

Due to growing demand from the foreign market, Ditta Musto had to renew its organisation and, above all, had to set up a technical department that would be able to respond to customers, re-adapt production, collaborate and grow alongside customers, satisfying the most demanding requests.

By making these changes, the company was able to supply many leading foreign companies with its products, and its production processes were completely transformed.

In this year, Ciriaco Musto retired and the new Musto et Bureau Srl (still known worldwide with the international brand Ditta Musto) was founded by Patrizia Musto, daughter of Ciriaco, together with her French partner Alain Bureau, who had been working as Technical Director at Ditta Musto since 1997.

This change was not only at corporate level, but it was also – and above all – a technical change, as it allowed the quality of production processes to be improved, bringing greater awareness of metallurgical techniques and manufacturing processes and ensuring high-quality products offering a high level of performance in a short amount of time while meeting customers' needs.

The products, which perfectly combined industrial technology and craftsmanship, were supplied to foundries worldwide, using carefully selected raw materials and striving for the highest quality and level of expertise to be applied in all production processes.

The most important feature of crucibles, besides the materials used, is their duration, on which Musto et Bureau Srl had based every aspect of the company's research and production. The value of the product lied precisely in its duration.

The other added value to their work was collaboration with customers, which is why the company dedicated the same interest and enthusiasm to each new product and to each new customer.

The skills acquired in the zinc and magnesium alloy sectors prompted Ditta Musto to expand its range of products; in particular, furnace products that met customers' needs, which mainly included requests to optimise production and energy costs.

|  |  |

Recently, the company also had the opportunity to build entire turnkey foundries thanks to the strong and stable business relationships established over the years.

When the French company Metafour ceased business, Ditta Musto decided to invest in it and opened a direct office in the country to be able to continue supplying all acquired customers, as well as to start providing an additional service for all the customers that the old Metafour company had supplied until then.

This new challenge also opened up a new opportunity for Musto et Bureau Srl, which was entering new sectors such as aluminum and other non-ferrous alloys, which it had not yet tackled until then.

Today, the company Musto et Bureau Srl is known worldwide with the international brand Ditta Musto and recognised for its high-quality production. The company has managed to demonstrate that even small businesses can offer quality and advanced technology and compete with dignity alongside larger businesses.

Ditta Musto believes that, in today's complex world, there is still room for companies that are committed to creating better products that meet customers' needs thanks to their expertise and professionalism, which leverage profits to create new initiatives capable of tangibly improving the compettiveness of the foundry world.

CERTIFICATIONS

The ISO 9001:2015 quality system is the focus of our business management. It is a “ Risk Management “ instrument for our Company because it ensure lasting customer satisfaction and better quality management.

Many are the benefits that our Company has reached through the new ISO 9001:2015

- Improved our company’s commitment to quality and customer satisfaction,

- Company’s products and services that take into account the needs of the customer and the mandatory and regulatory requirements,

- Better control of the Company of the continuous improvement of its performance market and greater competitiveness,

- Better results in organizational terms , concerning improved internal and external communication, and in efficiency and effectiveness.

PRESS

This section is

Please come back soon!